MSc Thesis: Low Power bi-directional reluctance actuator

I chose for the Mechatronic System Design track because of the multi-disciplinair approach. Mechanical, electronic and informatica are working together to create a high tech system. Building (electric) race vehicles, even more disciplines are involved.

Next to my thesis, I took the time to learn all about the available sensors, actuators and controllers in the MSD lab. I enjoyed teaching people about motion control and dynamics during my thesis. The result was a Low Power bi-directional reluctance actuator. The goal was to use the coarse stage for the high (de)acceleration to maximize the throughput of IC-wafers while keeping the heat dissipation in the fine stage to a minimum. In a repetitive environment, feed-forward controller can be used instead of the slower feed-back controller.

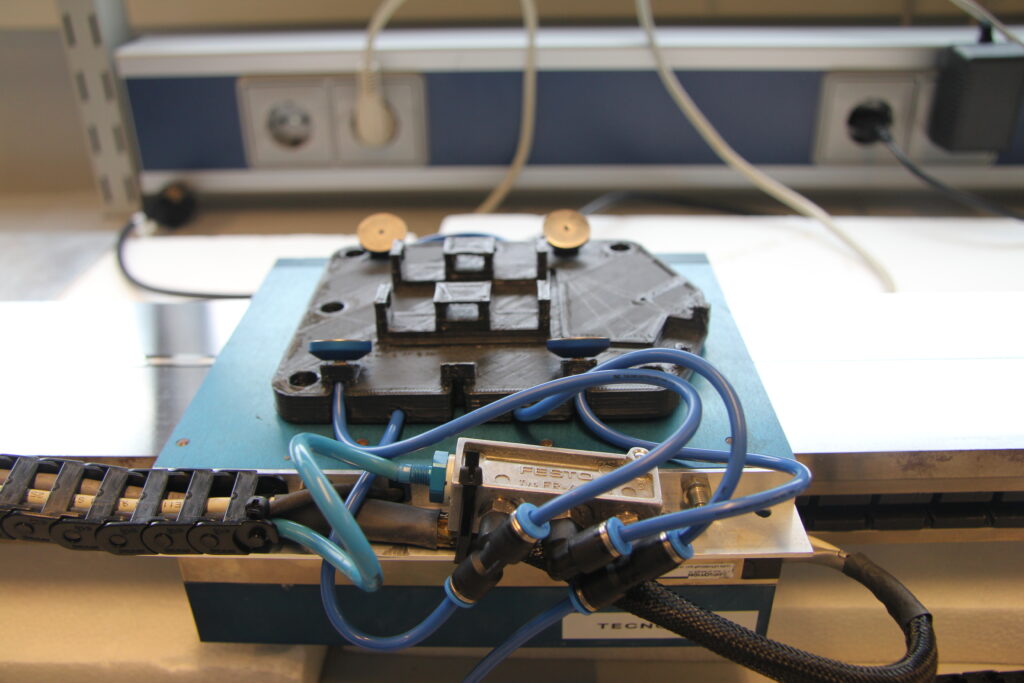

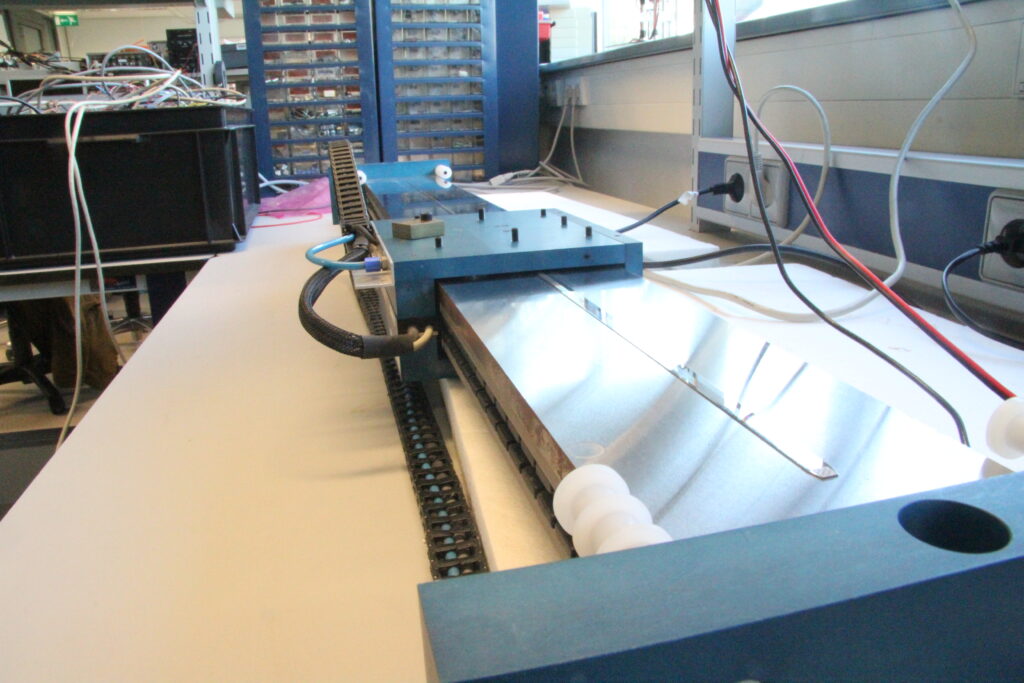

Coarse Stage

First step was to get a high performance coarse stage. So I used A. van Beek old demo stage with a Lorentz actuator for high (de)acceleration and air-bearings for low-friction.

The power electronics was done with an off-the-shelf amplifier that had multiple control modes. Acceleration, Speed and Position. The first tests were done using the built-in speed control. The position was determined using a high grade relative optical sensor.

MATLAB®/Simulink with a dSPACE setup was used to get more control over the motion of the coarse stage. dSPACE can be seen as a very expensive high-performance Arduino controller with multiple A/D, D/A with their DSP chips and I/O’s controlled by FPGA chips. And it has great graphical dashboard functionality together with Simulink.

Fine Stage

Reluctance actuators are known as a simple electromagnet to have a high holding force. For example the electromagnet on a door or even a junkyard magnet.

It was a challenge to create a bi-directional reluctance actuator. Magnetic Force is dependent on the magnetic flux in the air-gap that flows through the core material. Permanent magnet generate a magnetic flux without creating any heat, using a small fine-wind coil. A bi-directional force is generated.

The high force coarse stage can manipulate the gap size of the fine stage and so use the permanent magnets to change the position of the fine stage. Using the own designed controller, the controller learns to minimize the heat dissipation in the fine stage and do the gap manipulation using the coarse stage. And so minimizing the heat dissipation in the fine stage.